Hoa tsebahala hore boleng ba li-carbide saw blades bo amana haufi-ufi le boleng ba lihlahisoa tse entsoeng.Khetho e nepahetseng le e utloahalang ea li-blades tsa carbide e bohlokoa haholo bakeng sa ho ntlafatsa boleng ba sehlahisoa, ho khutsufatsa nako ea ho sebetsa, le ho fokotsa litšenyehelo tsa ho sebetsa.

Mohlomong u tšoenyehile ka mokhoa oa ho khetha!Joale ka kopo bala sehlooho sena ka mamello, ke tšepa hore se lokela ho khona ho u thusa haholoanyane.

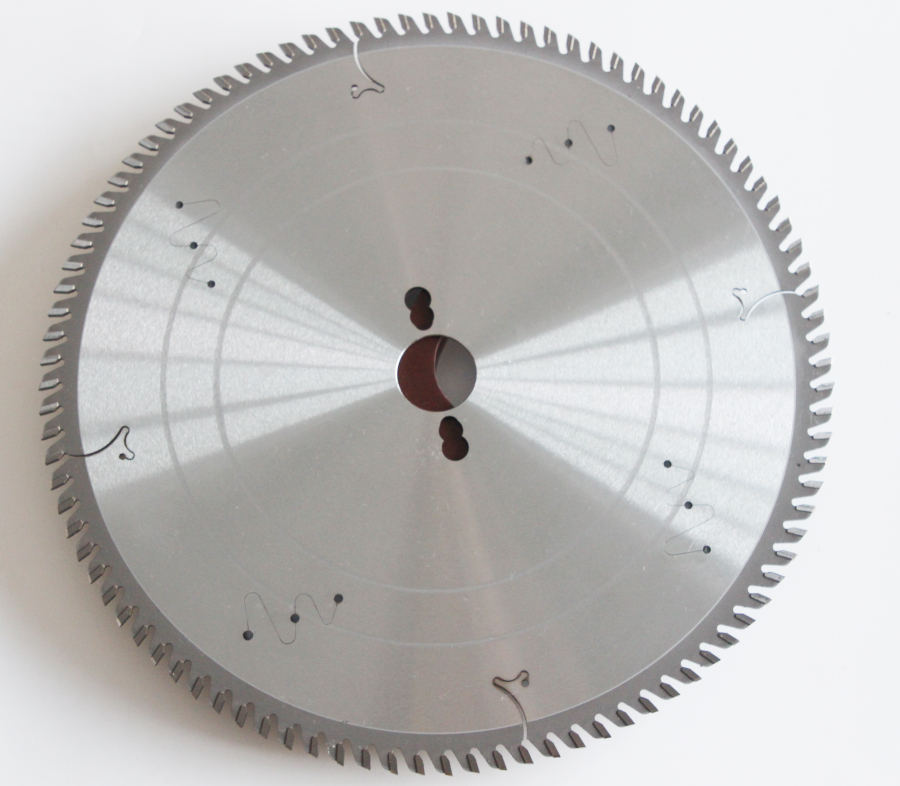

Li-blades tsa Carbide li kenyelletsa likarolo tse fapaneng tse kang mofuta oa hlooho ea li-alloy cutter, thepa ea substrate, bophara, palo ea meno, botenya, profil ea leino, angle le sebaka.Mekhahlelo ena e khetholla bokhoni ba ho sebetsa le ts'ebetso ea ho itšeha ea lehare la sakha.Ka hona, ha u khetha lehare la sakha, ho hlokahala hore u khethe lehare la sakha ka nepo ho latela mofuta oa thepa ea ho sakha, botenya, lebelo la ho sakha, tataiso ea ho sakha, lebelo la ho fepa, le bophara ba tsela ea sakha.

Taba ea pele, khetho ea mefuta e samente ea carbide.

Mefuta e sebelisoang hangata ea carbide e entsoeng ka samente ke tungsten-cobalt le tungsten-titanium.Hobane carbide e entsoeng ka samente e thehiloeng ho tungsten-cobalt e na le matla a ho hanyetsa, e sebelisoa haholo indastering ea ho lokisa lehong.Ha litaba tsa cobalt li ntse li eketseha, matla a ts'usumetso le matla a flexural a alloy a tla eketseha, empa ho thatafala le ho hanyetsa ho apara ho tla fokotseha.Khetha ho latela boemo ba sebele.

Ea bobeli, khetho ea substrate.

1. 65Mn tšepe ea selemo e na le elasticity e ntle le polasetiki, thepa ea moruo, ho thatafala ha mocheso oa mocheso, mocheso o tlase o futhumatsang, deformation e bonolo, 'me e ka sebelisoa bakeng sa li-blades tsa saw tse hlokang litlhoko tse tlaase tsa ho itšeha.

2. Carbon tool steel e na le k'habone e phahameng le conductivity e phahameng ea mocheso, empa ho thatafala ha eona le ho roala ho hanyetsa ho theoha haholo ha ho pepesehile mocheso oa 200 ℃-250 ℃, ho senyeha ha mocheso oa mocheso ho hoholo, ho thatafala ha boima, 'me nako e telele ea mocheso e bonolo. ho petsola.Etsa lisebelisoa tsa moruo bakeng sa lisebelisoa.

3. Ha ho bapisoa le tšepe ea lisebelisoa tsa carbon, tšepe ea tšepe ea alloy e na le ho hanyetsa mocheso o motle, ho hanyetsa ho apara le ho sebetsana hantle le ts'ebetso.Thempereichara ea deformation ea mocheso ke 300 ℃-400 ℃, e loketseng ho etsa li-blade tsa alloy circular saw.

4. Lisebelisoa tsa tšepe tsa lebelo le phahameng li na le boima bo botle, bo thata bo matla le bo thata, le ho senyeha ho fokolang mocheso.Ke tšepe e matla haholo e nang le thermoplasticity e tsitsitseng, 'me e loketse ho etsa li-saha tsa boleng bo holimo tse phahameng haholo.

Ea boraro, khetho ea bophara.

Bophara ba lehare la sakha bo amana le lisebelisoa tsa ho sakha tse sebelisoang le botenya ba mosebetsi oa ho sakha.Bophara ba lehare la saw bo nyane, 'me lebelo la ho itšeha le batla le le tlase;lehare le leholo la sakha le na le litlhoko tse phahameng holim'a lehare la sakha le lisebelisoa tsa ho sakha, 'me katleho ea ho sakha le eona e phahame.Bophara bo ka ntle ba lehare la sakha bo khethoa ho latela mefuta e fapaneng ea selikalikoe sa selikalikoe.

Ea bone, khetho ea palo ea meno.

Ka kakaretso, ha palo ea meno e ntse e eketseha, likarolo tse ngata tsa ho itšeha li ka khaoloa ka nako e le 'ngoe, ho ntlafatsa ts'ebetso ea ho itšeha, empa meno a ho itšeha a hloka ho sebelisa carbide e ngata ea samente, theko ea lehare la saw e phahame, empa meno a teteaneng haholo , Molumo oa chip pakeng tsa meno o fetoha o monyenyane, oo ho leng bonolo ho etsa hore lehare la saw le futhumale;ho phaella moo, ho na le meno a mangata haholo a sakha.Ha palo ea lijo e sa lumellane, palo ea ho itšeha ea leino le leng le le leng e nyenyane, e leng ho tla mpefatsa khohlano pakeng tsa sekhahla sa ho itšeha le workpiece, le ho ama bophelo ba tšebeletso ea ho itšeha.Hangata karohano ea meno ke 15-25mm, 'me palo e lekaneng ea meno e lokela ho khethoa ho ea ka thepa e lokelang ho hahoa.

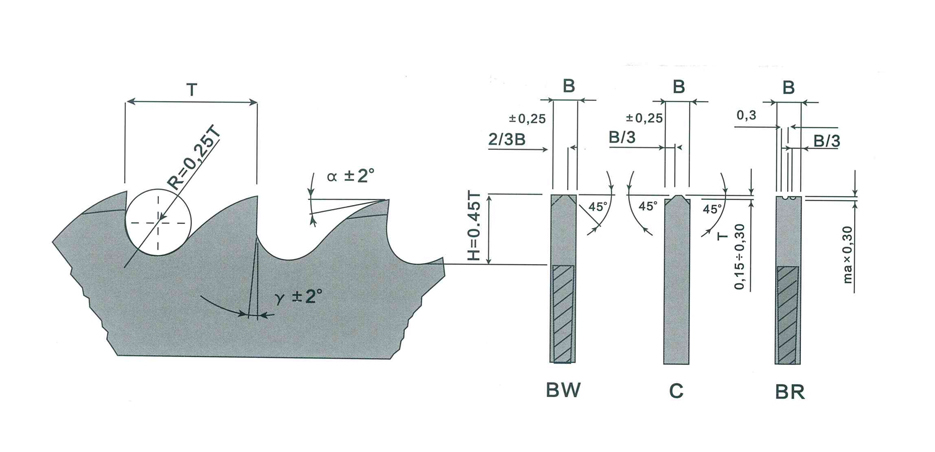

Ea bohlano, khetho ea boemo ba meno.

1.Meno a ka ho le letšehali le a nepahetseng a sebelisoa ka ho fetisisa, lebelo la ho itšeha le potlakile, 'me ho sila ho batla ho le bonolo.E loketse bakeng sa ho rema le ho tšela li-profiles tse fapa-fapaneng tse bonolo le tse thata tsa lehong le mapolanka a mangata, mapolanka a mangata, liboto tsa likaroloana, joalo-joalo. ho seha mefuta eohle ea mapolanka ka li-node tsa lifate;li-blades tsa leino le letšehali tse nang le li-rake angle tse mpe hangata li sebelisoa bakeng sa ho pata ka lebaka la meno a tsona a bohale le boleng bo botle ba ho itšeha, a loketseng liphanele.

2. Leqhubu la leino le sephara la saw le bohale, lebelo la ho itšeha le lieha, 'me ho sila ho bonolo ka ho fetisisa.E sebelisoa haholo-holo bakeng sa ho sakha ka lehong le tloaelehileng, ka theko e tlaase.E sebelisoa haholo bakeng sa li-blade tsa aluminium tse nang le li-diameter tse nyane ho fokotsa ho khomarela nakong ea ho itšeha, kapa bakeng sa li-blades tsa grooving saw ho boloka tlase ea groove e bataletse.

3. Meno a sephara a lere ke motsoako oa meno a trapezoidal le meno a bataletseng.Ho sila ho rarahane le ho feta.E ka fokotsa ho phatloha ha veneer nakong ea sakha.E loketse bakeng sa ho sakha liphanele tse fapaneng tse nang le lehong le habeli le nang le mapolanka a sa cheng.E le ho thibela ho khomarela, aluminium sakha di-blades hangata sebelisa di-blades sakha le palo e kholo ea meno a lere bataletse meno.

4. Meno a lere e sothehileng a atisa ho sebelisoa karolong e ka tlaase ea sekotjana sa sakha sa pane.Ha o sakha phanele e entsoeng ka lehong e nang le lifahleho tse peli, sakha ea slot e lokisa botenya hore e qetelle ho phunya bokaholimo, ebe lisakha e khōlō e phethela mosebetsi oa ho sakha boto.Thibela ho phunyeha ha bohale lehlakoreng la sakha.

Nako ea poso: Oct-11-2021