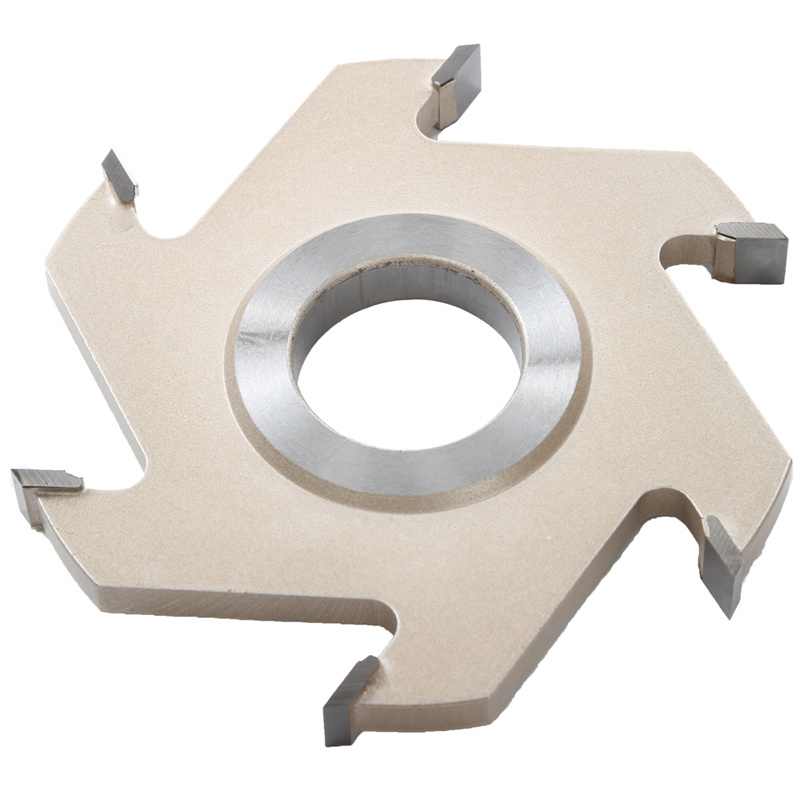

125mm Dia, Carbide Tipped, Grooving Cutter le Chip Limitation, Meno a 6

Tlhaloso e Khutšoanyane:

TLHALOSO

Sehahi sena sa ho qetela sa grooving se na le sesebelisoa sa tšepe se apereng ka thata se nang le lithipa tse tšeletseng tsa tungsten carbide.E loketse ho hlahisa li-grooves tse nepahetseng le li-slots holim'a thepa.

- Carbide-Tipped bakeng sa ho khaola li-grooves haufi le lijo-thollo

- Haholo-holo e loketse ho hlahisa li-grooves le slots ka softwood, hardwood, le liboto tse entsoeng ke motho (tse nang le kapa ntle le ho roala) holim'a mochini oa spindle

- E ka sebelisoa le mehele ea spacer bakeng sa ho kopanya ha kama

LBH

1 Na u feme?

Ee, re litsebi tsa feme ea blade ea sakha ka lilemo tse 15, ho feta 15,000 m² ea lithupelo tsa tlhahiso le mela e 15 ea tlhahiso.

2 O na le tokelo ea ho rekisa kantle ho naha?

Ee, re na le setifikeiti sa thomello.'Me re na le lilemo tse 10 tsa phihlelo e ikemetseng ea ho romela thepa.Haeba u na le lipotso mabapi le ho tsamaisa thepa le tumello ea meetlo, re ka boela ra u thusa ho li rarolla.Pele thepa ea hau e tloha fekthering ea rona, re ka u fa polokelo ea mahala bakeng sa hau.

Ngola molaetsa wa hao mona mme o re romele wona